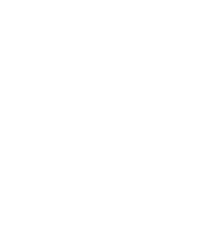

At the SinoCorrugated 2025 exhibition, Hanway introduced its latest innovation, Ultra2500W Pro, showcasing its comprehensive advantages through a live demonstration of automated production and coated color printing solutions.

Market Growth Drivers

The packaging machinery market is experiencing significant growth. A recent report by Research and Markets predicts the market will rise from USD 49.02 billion in 2023 to USD 51.65 billion in 2024, and is projected to reach USD 71.07 billion by 2030, growing at a CAGR of 5.44%. Key factors driving this growth include:

·Increased automation and robotics integration

·Technological advancements such as IoT and AI for smart packaging solutions

·Rising industry emphasis on sustainable and eco-friendly packaging machinery, driven by stringent regulations and consumer awareness

This trend presents substantial market opportunities for machinery that can seamlessly integrate with existing production lines to enhance efficiency. Hanway is capitalizing on this trend by offering advanced automation technology to transform the packaging production process.

Integrated Automated Production

Full-Process Automation:

"Paper Loading – Printing – Drying – Unloading"

Hanway has a proven track record in delivering automated digital production line solutions. The new Ultra2500W Pro efficiently integrates an automatic feeder with a drying module to achieve full-process automation, from "paper loading, printing, drying, to unloading." This innovative solution addresses common pain points in printing workshops, such as printing position Offset, material waste, and efficiency bottlenecks.

·High Automation, Reduced Labor Costs, and Enhanced Efficiency:

Traditional packaging production involves repetitive manual operations for paper loading, printing, and unloading. The Ultra2500W Pro integrates a fully automatic feeder module with the new generation Ultra2500W unit, streamlining the entire process. This enables "one-touch" printing of multiple-version orders, even with large-format corrugated materials, significantly reducing the need for manual labor and boosting efficiency. The solution also supports the integration of additional functional modules like drying and varnishing, unlocking the benefits of large-scale automated production.

Automatic Feeder Module:

o Flexible paper feeding: supports both continuous and intermittent modes.

o Vacuum suction feeding: ensures damage-free handling of the cardboard.

o Automatic control of suction cup quantity: adapts to various paper sizes.

o Basket-type pallet: automatically adjusts height for easy paper loading and unloading.

·Saving Manual Handling and Scheduling Time, Reducing Errors and Waste:

Operators can manage batch, multi-version orders with a single click, and change materials without machine downtime. The equipment automatically adapts to different sheet sizes, enabling continuous and efficient switching between orders. This not only enhances production flexibility and efficiency but also minimizes human error, waste, and production bottlenecks.

·Precise Control Across Production Stages, Ensuring Consistent Product Quality:

The Ultra2500W Pro features an innovative visual step-drive closed-loop control system and direct drive system, enabling high-precision positioning and pattern alignment in complex environments. By detecting displacement errors, multi-pass printing stability is ensured, eliminating the misregistration and ghosting issues associated with traditional mechanical return. The system is also equipped with anti-collision protection, a water-cooling system, a humidification function, and an optimized ink delivery system, ensuring consistent print quality.

Expanding High-Value Packaging Orders

Effortless Printing of Coated Color Boxes, Cartons, and Displays

In addition to streamlining production, the Ultra2500W Pro excels in coated color printing, supporting paperboard thicknesses from 0.3 to 15 mm. It handles both coated corrugated and coated cardboard, delivering print quality comparable to offset printing. This capability allows for the production of high-value packaging, such as coated color boxes, cartons, and displays, and also opens opportunities in advertising, exhibition displays, commercial showcases, and other sectors.

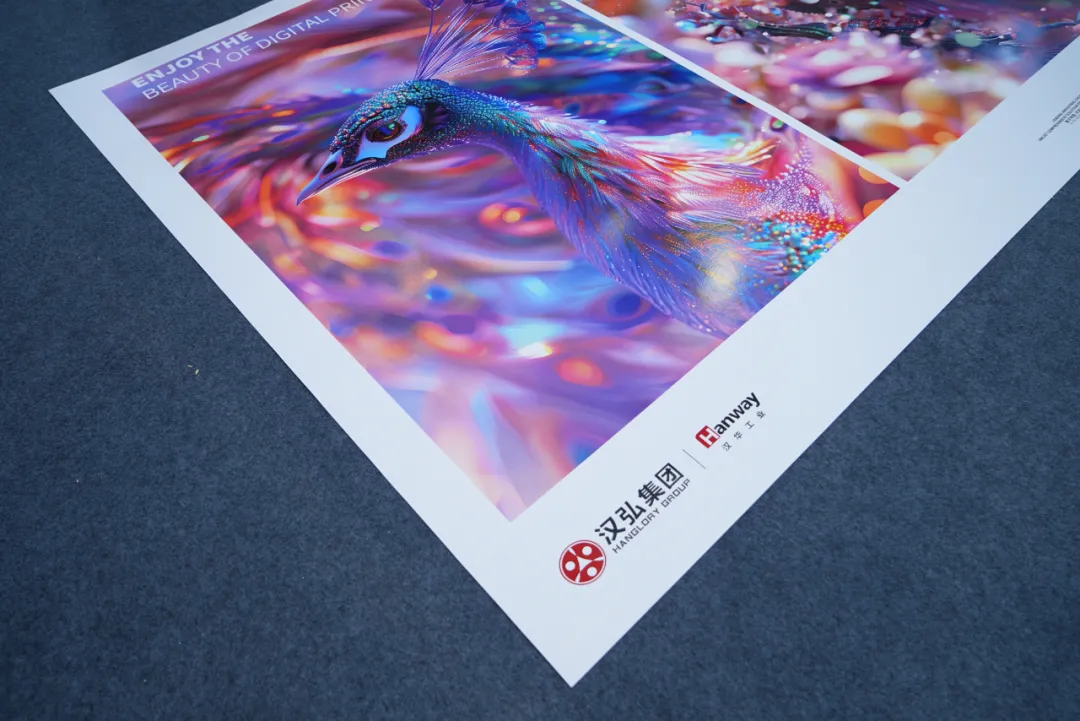

Live Print Samples

·Peacock Print:

"This full-color print showcases the Ultra2500W Pro's ability to deliver rich color saturation and exceptional detail. The background gradient transitions smoothly, highlighting the lifelike peacock. The peacock feathers display a vibrant spectrum of colors, including blues, greens, purples, golds, and oranges. Fine details, such as the color variations around the peacock's eyes and the color distribution of the tail feather patterns, are rendered with clarity and natural transitions. The upgraded wide-format printhead enables a single-pass width of 432mm, efficiently meeting the demands of large-format, full-color printing."

·Appliance and Furniture Box Prints:

"These large-format coated color boxes demonstrate the Ultra2500W Pro's performance in industries with high image quality and wide-format requirements. The elements, including bedding, figures, and appliances, are reproduced with precision. The printer also excels in printing large solid color areas, as seen in the uniform red and black backgrounds, which make the product stand out. Fine details such as product parameters, instructions, micro text and high-density barcodes are printed with sharpness and clarity."

Company :Shenzhen Hanglory Digital Printing Group Co., Ltd

Phone:0755-23080896 / 0755-23062862

Fax:0755-23217841

Address:HanGlory Headquarters (No. 28, Gaoke Avenue, Baolong Subdistrict, Longgang District, Shenzhen, China)

E-mail :info@hanglorygroup.com

Are you ready? Then contact us