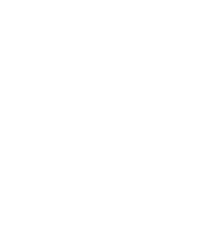

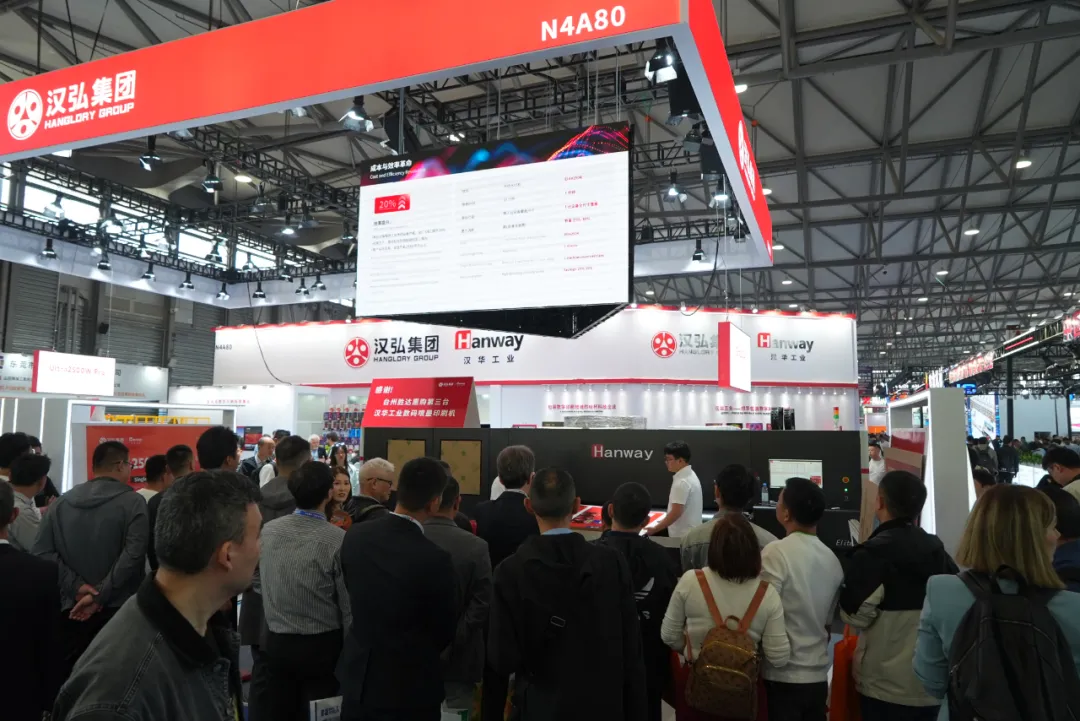

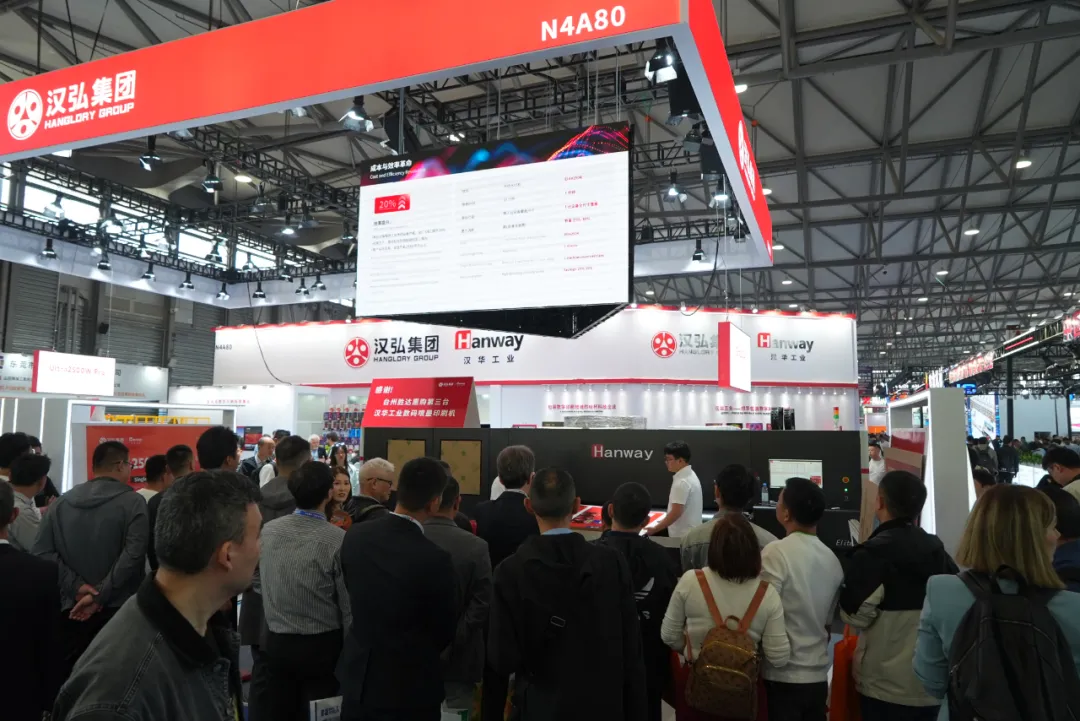

Faced with increasing competition in the corrugated packaging industry, businesses are urgently seeking breakthroughs in "cost reduction and efficiency enhancement." Hanway is highlighting its Single Pass solution, the Elite2504, at the China International Corrugated Exhibition. The Elite2504 offers a strong value proposition and aims to support corrugated packaging plants in transitioning their yellow and white cardboard orders.Hanway will be showcasing the Elite2504 at Booth N4A80 at SinoCorrugated 2025 in Shanghai, China from April 8-10, 2025.Efficiency Focus:

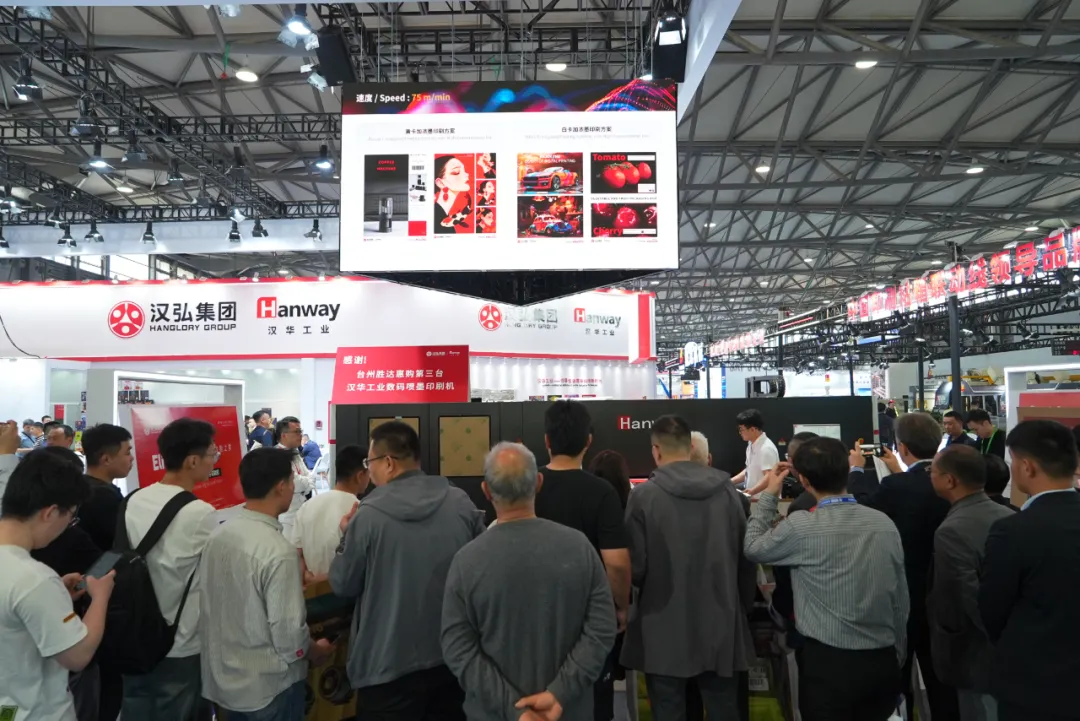

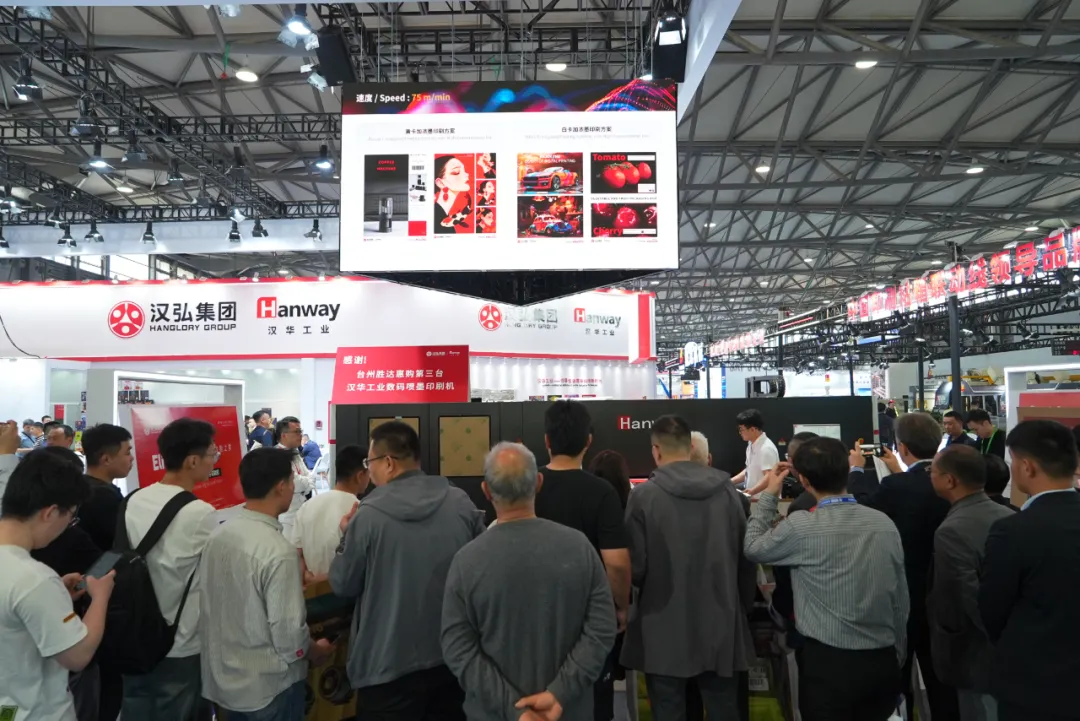

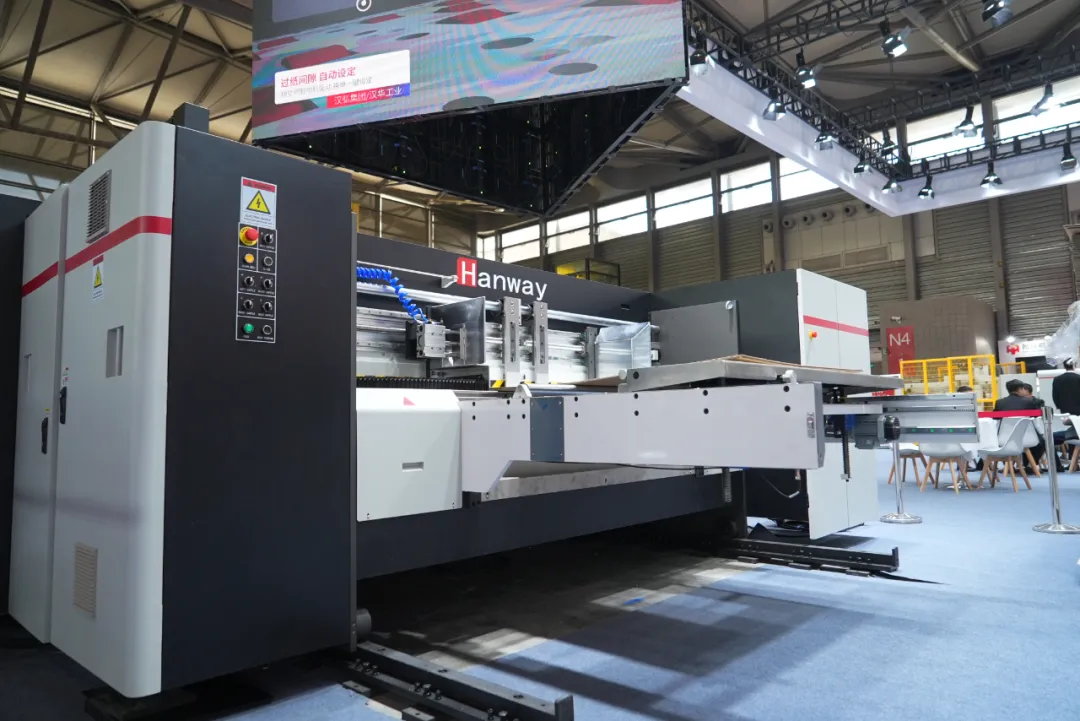

Flexible and Efficient Order DeliveryBuilding upon the core technology and stability of Hanway's Single Pass wide-format flagship Glory2504, the Elite2504 boasts a production speed of 75-100m/min. This enables the efficient and continuous production of various yellow and white cardboard orders. Whether handling high-volume demands during e-commerce peaks and promotional events or ensuring the urgent delivery of rush orders, the Elite2504's production efficiency ensures rapid order fulfillment for customers.

Specific features contributing to efficient production include:· Upgraded Front-Edge Paper Feeding Technology: This enhanced paper feeding method achieves flexible and precise paper delivery, significantly improving the flexibility and adaptability of the paper-loading process.· Highly Efficient and Seamless Job Change Software: This software enables rapid and accurate identification of order information, allowing for one-time output of orders with the same specifications and a smooth, efficient production flow. It also supports non-stop file loading, eliminating the need for companies to invest in additional servers or storage space for file loading.· Printhead Water Cooling & Color Management (Color Difference Compensation): To address the issue of printhead overheating during prolonged continuous printing, which can affect print quality, the Elite2504 incorporates a printhead water-cooling kit. This kit supports 24/7 uninterrupted printing, preventing color variations caused by increased printhead temperatures and ensuring long-term print quality and stability. Through professional color management and precise color difference compensation, the Elite2504 ensures color consistency and accurate reproduction of spot colors across various types of yellow/white card orders, including multi-SKU orders, repeat orders, and long runs.

Additional Advantages and FeaturesElite2504 offers several additional advantages:·Ink Waste Recycling System (WIRS): The system collects, processes, and reuses ink waste generated during printing, achieving near-zero waste discharge and reducing ink costs by 25-30% compared to traditional systems. It also has international environmental certifications (Reach, RoHS, FDA) and supports food-grade applications.·Self-Developed Proprietary Water-Based Pigment Inks: The printer uses waterproof and eco-friendly self-developed water-based pigment inks with scratch resistance meeting traditional water-based printing standards. The inks also provide smooth, stable inkjet performance at high speeds (75-100m/min) without nozzle clogging. Multiple ink options are available, including priming + water-based pigment and high-concentration ink.·High Print Quality and Variable Data Printing: The Elite2504 is compatible with large-format and multi-color printing. It delivers color density comparable to water-based printing on yellow card and color saturation approaching offset quality on white card. It also supports variable data printing, including micro-fine text and high-density barcodes (reaching grade A).·Integrated Production Line Solution: Multi-Process Modules (Self-Config or Optional) Digital Integrated Production Line: Main Machine (Feeding + Priming + Printing) + Drying + Varnishing + Stacking·Automatic Maintenance System: The system includes automatic nozzle cleaning, self-diagnostic fault detection and component monitoring, and a carriage collision protection system.